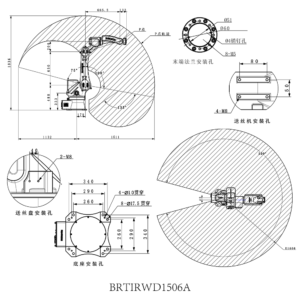

BRTIRWD1506A Six-axis Industrial Robot

Product Description

The BRTIRWD1506A is a Six-Axis Industrial Robot developed by Borunte specifically for welding applications. This advanced robot is designed to handle welding tasks with high precision and flexibility, making it an ideal solution for modern manufacturing environments.

Design Features

- Compact Structure: The robot has a small size and light weight, making it easy to integrate into existing production lines.

- 1600mm Arm Span: Provides a wide reach, suitable for handling materials across large workspaces.

- Maximum Load of 6kg: Capable of handling medium-sized components efficiently.

- Hollow Wrist Structure: The hollow design of the wrist makes wiring more convenient and allows for greater flexibility in movement.

Protection and Precision

- High Protection Level: IP54:

- Dustproof and Waterproof: Ensures the robot can operate in environments with dust and splashing water, providing robust protection.

- High Precision: Features a repeated positioning accuracy of ±0.05mm, delivering consistent and reliable performance.

Applications

- Welding: Ideal for automated welding applications, ensuring consistent and high-quality welds.

- Handling: Suitable for moving and positioning components in welding and related processes.

- Loading and Unloading: Perfect for automating the loading and unloading of materials in welding operations.

- Assembly: Efficient for precise assembly tasks in industries where welding is a key process.

Performance Benefits

- Enhanced Efficiency: The BRTIRWD1506A is designed to perform welding tasks quickly and reliably, increasing overall production efficiency.

- Consistent Quality: High precision and repeated positioning accuracy ensure that welds meet stringent quality requirements.

- Operator Safety: By automating tasks in hazardous environments, the robot helps create a safer work environment.

- Reduced Labor Costs: Automates labor-intensive processes, allowing factory personnel to focus on more value-added activities.

- Simple Maintenance: The integrated control system and robust design make maintenance straightforward and reduce downtime.

Control System

- Six-Axis Drive-Control Integrated System:

- Fewer Signal Lines: Simplifies installation and maintenance.

- Long-Distance Communication: Supports reliable operation in large-scale manufacturing environments.

- Good Expansion Performance: Offers excellent adaptability to various production settings.

- Strong Anti-Interference Ability: Ensures high accuracy and reliability in operation.

The BRTIRWD1506A is a reliable and versatile solution for modern manufacturing needs. It promises long-term benefits in terms of efficiency, precision, and cost savings, making it an essential investment for any factory looking to optimize its welding processes and ensure operator safety.

Main Specifications

Arm span (mm): 1600

Repeat positioning accuracy (mm): ±0.05

Maximum load (kg): 6

Power capacity (kVA): 4.64

Weight (kg): Approx. 166

Main Specifications

| Item | Scope | Maximum Speed | |

| Arm | J1 | ±165° | 163°/s |

| J2 | -100°/+70° | 149°/s | |

| J3 | ±80° | 223°/s | |

| Wris | J4 | ±150° | 169°/s |

| J5 | ±110° | 270°/s | |

| J6 | ±360° | 398°/s | |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.