Single-section Single-arm Three-axis servo Manipulator

Product Description

The Single-Section Single-Arm Three-Axis Servo Manipulator is specifically designed for the finished product removal of various horizontal injection molding machines ranging from 60T to 280T. This advanced manipulator is a versatile and efficient solution for modern manufacturing environments.

Design Features

- Single-Section Arm: Provides a compact and flexible design, ideal for a wide range of applications.

- Three-Axis AC Servo Drive: Ensures accurate positioning and fast speed, making it suitable for quick removal or in-mold labeling, in-mold inserts, and other special product applications.

Performance Benefits

- Accurate Positioning: The manipulator’s precision ensures consistent and reliable product handling.

- Fast Speed: High-speed operation reduces cycle times, enhancing overall production efficiency.

- Long Life: The robust design and high-quality components contribute to a longer operational life.

- Low Failure Rate: Minimizes breakdowns and downtime, ensuring continuous and smooth production.

Production Enhancements

- Increased Productivity: Installation of the manipulator can increase production capacity by 10-30%.

- Low Product Defect Rate: Helps in maintaining high product quality by reducing defects.

- Operator Safety: Ensures a safer work environment by automating repetitive and potentially hazardous tasks.

- Labor Reduction: Automates labor-intensive tasks, allowing factory personnel to focus on more value-added activities.

- Accurate Production Volume Control: Enables precise control over production volume, reducing waste.

- Timely Delivery: Ensures that products are delivered on time by optimizing the production process.

Control System

- Three-Axis Drive-Control Integrated System: Features few signal lines, simplifying installation and maintenance.

- Long-Distance Communication: Supports reliable operation even in large-scale manufacturing environments.

- Good Expansion Performance: Offers excellent adaptability to various production settings.

- Strong Anti-Interference Ability: Ensures high repeat positioning accuracy and the ability to control multiple axes simultaneously.

Reliability and Support

- Two-Year Warranty: Provides comprehensive coverage for two years, offering peace of mind.

- OEM Support: Offers customization options to meet specific factory requirements.

The Single-Section Single-Arm Three-Axis Servo Manipulator is a reliable and versatile solution for enhancing the efficiency and reliability of your injection molding processes. It is an investment that promises long-term benefits in terms of productivity, quality, safety, and cost savings.

Introduction to Injection Molding Manipulators Manufactured in China

Main Specifications

|

Model |

Power Source(kVA) | Recommended I.M.M (ton) | Traverser Driven | Model of EOAT | Traverse Stroke (mm) | Crosswise Stroke (mm) | Vertical Stroke (mm) | Max.Loading (kg) | Dry Take Out Time (sec) | Dry Cycle Time(sec) | Air Consumption (NI/cycle) | Weight (kg) |

|

S5-700ID |

3 |

60T-120T | AC Servo motor | Two suctions

Two fixtures |

1230 | 770 | 700 | 5 | 1.3 | 6.8 | 4 | 250 |

|

S5-800ID |

120T-160T |

800 |

1.4 |

6.9 |

||||||||

| S5-900ID | 3.5 | 200T-280T | 1390 | 890 | 900 | 1.5 | 7.1 |

260 |

Model representation :I: Single section type W: Telescopic type S: Single arm D: Product arm+ runner arm. S3: Three-axis driven by AC Servo Motor S5: Five-axis driven by AC Servo Motor (Traverse-axis、Vertical-axis + Crosswise-axis)

The above-mentioned cycle time are the results of our company’s internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

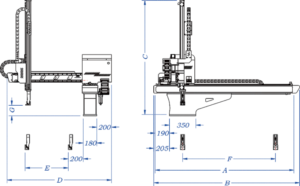

| Model | A | B | C | D | E | F | G |

| 700 | 1840 | 1940 | 1456 | 1390 | 870 | 1230 | 130(32) |

| 800 | 1580 | ||||||

| 900 | 2000 | 2100 | 1700 | 1510 | 690 | 1390 |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.