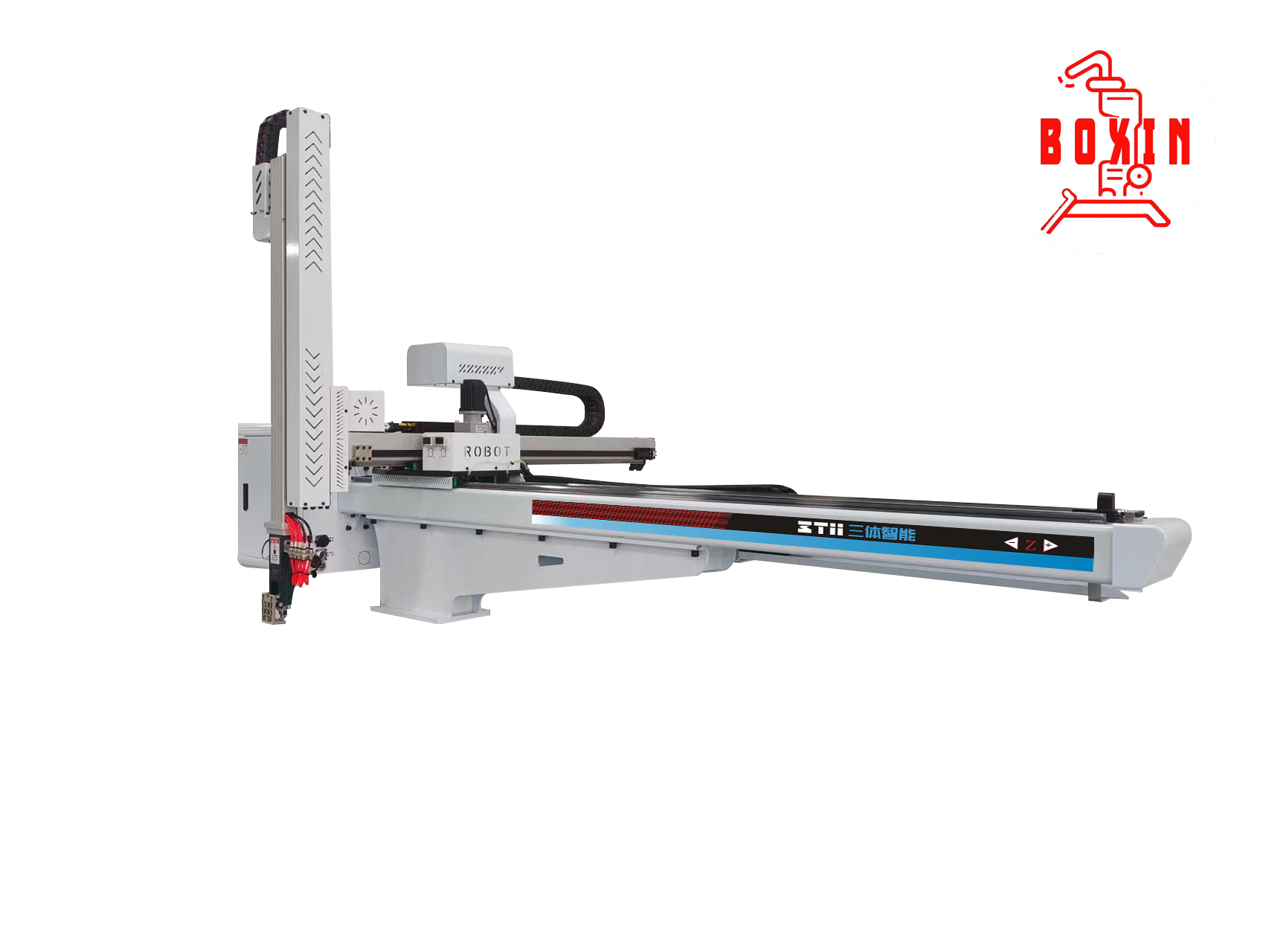

Bull Head Manipulator

Product Description

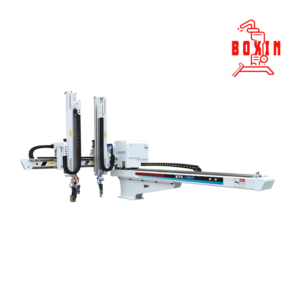

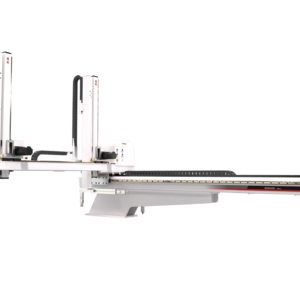

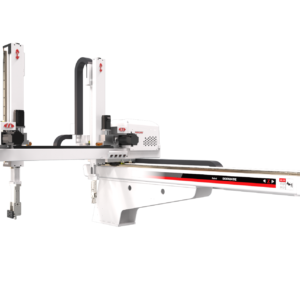

The Bull Head Manipulator is a high-performance robotic solution designed for plastic injection molding machines ranging from 160 to 4000 tons. It is specifically tailored to handle fast removal and complex angle applications, making it ideal for long-shaped products such as automotive parts, washing machines, and household appliances. The manipulator features a double-section arm type and a single arm, both driven by a three-axis AC servo drive. This advanced drive system allows for faster retrieval speeds, saving more time compared to similar models. Accurate positioning, high speed, long life, and a low failure rate are key attributes that set the Bull Head Manipulator apart.

In addition to the standard three-axis AC servo drive, the Bull Head Manipulator offers an optional five-axis AC servo drive. The A-axis can rotate 360°, and the C-axis can rotate 180°, providing the flexibility to freely position and adjust the fixture angle. Both drive systems ensure long life, high precision, low failure rate, and simple maintenance, making them a reliable choice for demanding production environments.

The integrated control system for the three-axis drive reduces the number of signal lines, supports long-distance communication, and offers excellent expansion performance. It also features strong anti-interference capabilities and high repeatability, allowing for simultaneous control of multiple axes. This system simplifies equipment maintenance and further reduces the failure rate, ensuring consistent and reliable operation.

Installing a Bull Head Manipulator can increase production capacity by 10-30%, reduce product defect rates, ensure operator safety, and minimize labor costs. It accurately controls production volume, reduces waste, and ensures timely delivery. Backed by a two-year warranty and comprehensive OEM support, the Bull Head Manipulator is a robust and efficient solution for modern manufacturing needs.

Key Features

Versatile Arm Types

- Double-section arm type for extended reach.

- Single arm for simpler and more compact tasks.

- Both types are driven by a three-axis AC servo drive.

Advanced Drive System

- Three-axis AC servo drive for faster retrieval speeds.

- Optional five-axis AC servo drive for greater flexibility.

- A-axis rotation angle: 360°.

- C-axis rotation angle: 180°.

- High precision, long life, and low failure rate.

Integrated Control System

- Fewer signal lines for simplified wiring.

- Long-distance communication capabilities.

- Excellent expansion performance.

- Strong anti-interference ability.

- High repeatability and simultaneous control of multiple axes.

Enhanced Productivity

- Increases production capacity by 10-30%.

- Reduces product defect rates.

- Ensures operator safety.

- Minimizes labor costs.

- Accurately controls production volume.

- Reduces waste and ensures timely delivery.

Comprehensive Support and Warranty

- Backed by a two-year warranty.

- Support customization and OEM

- Ensures long-term reliability and customer satisfaction.

The Bull Head Manipulator is the perfect solution for production managers and factory operators looking to enhance efficiency, accuracy, and safety in their injection molding processes. Its advanced features and robust design make it a reliable and cost-effective investment for modern manufacturing environments.

Introduction to Injection Molding Manipulators Manufactured in China

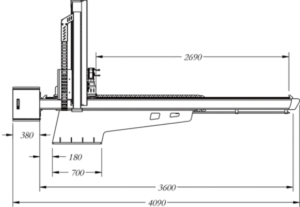

Main Specifications

|

Model |

Power Source(kVA) | Recommended I.M.M (ton) | Traverser Driven | Model of EOAT | Traverse Stroke (mm) | Crosswise Stroke (mm) | Vertical Stroke (mm) | Max.Loading (kg) | Dry Take Out Time (sec) | Dry Cycle Time(sec) | Air Consumption (NI/cycle) | Weight (kg) |

|

S3-TN1000WS |

3.2 | 200T-350T | AC Servo motor | Two suctions

Two fixtures |

1360 | 770 | 1000 | 8KG-10KG | 1.5 | 6 | 3.2 | 270 |

|

S3-TN1100WS |

300T-400T | 1100 | ||||||||||

|

S3-TN1200WS |

300T-500T |

1560 |

890 | 1200 | 1.8 | 7 | 300 | |||||

| S3-TN1300WS |

400T-700T |

1660 |

1300 |

|||||||||

|

S3-TN1500WS |

3.4 | 600T-800T | 2100 | 1080 | 1500 | 10KG-20KG | 2.7 | 10 | 15 | 400 | ||

|

S3-TN1800WS |

700T-1000T |

2690 |

1530 | 1800 | 5 | 17 | 680 | |||||

| S3-TN2000WS |

800T-1200T |

1530 |

2000 |

6.3 |

||||||||

|

S3-TN2200WS |

6.6 | 1200T-1800T | 2690 | 1530 | 2200 | 20KG-60KG | 6.6 | 25 | 17 | 1450 | ||

| S3-TN2500WS |

1800T-2200T |

1630 |

2500 |

|||||||||

|

S3-TN3000WS |

2200T-3000T | 2890 | 1730 | 3000 | 9 | 37 |

1800 |

Model representation :I: Single section type W: Telescopic type S: Single arm D: Product arm+ runner arm. S3: Three-axis driven by AC Servo Motor S5: Five-axis driven by AC Servo Motor (Traverse-axis、Vertical-axis + Crosswise-axis)

The above-mentioned cycle time are the results of our company’s internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

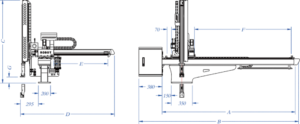

| Model | A | B | C | D | E | F | G |

| 650 | 1840 | 2300 | 1150 | 1320 | 650 | 1200 | 130(32) |

| 900 | 2000 | 2460 | 1270 | 1440 | 770 | 1360 | |

| 1000 | 1330 | ||||||

| 1200 | 2200 | 2660 | 1450 | 1560 | 890 | 1560 | 80(40) |

| 1300 | 2300 | 2760 | 1510 | 1660 |

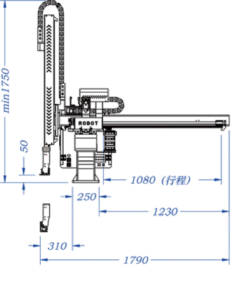

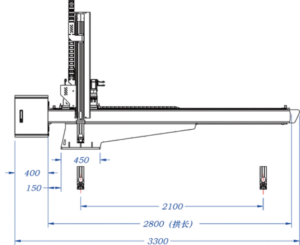

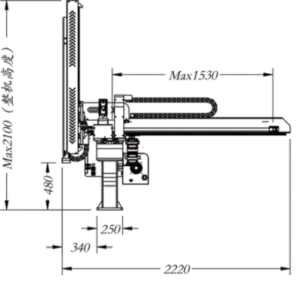

| Model | Machine height(mm) |

| 1800 | 2100 |

| 1900 | 2160 |

| 2000 | 2220 |

| 2200 | 2340 |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.