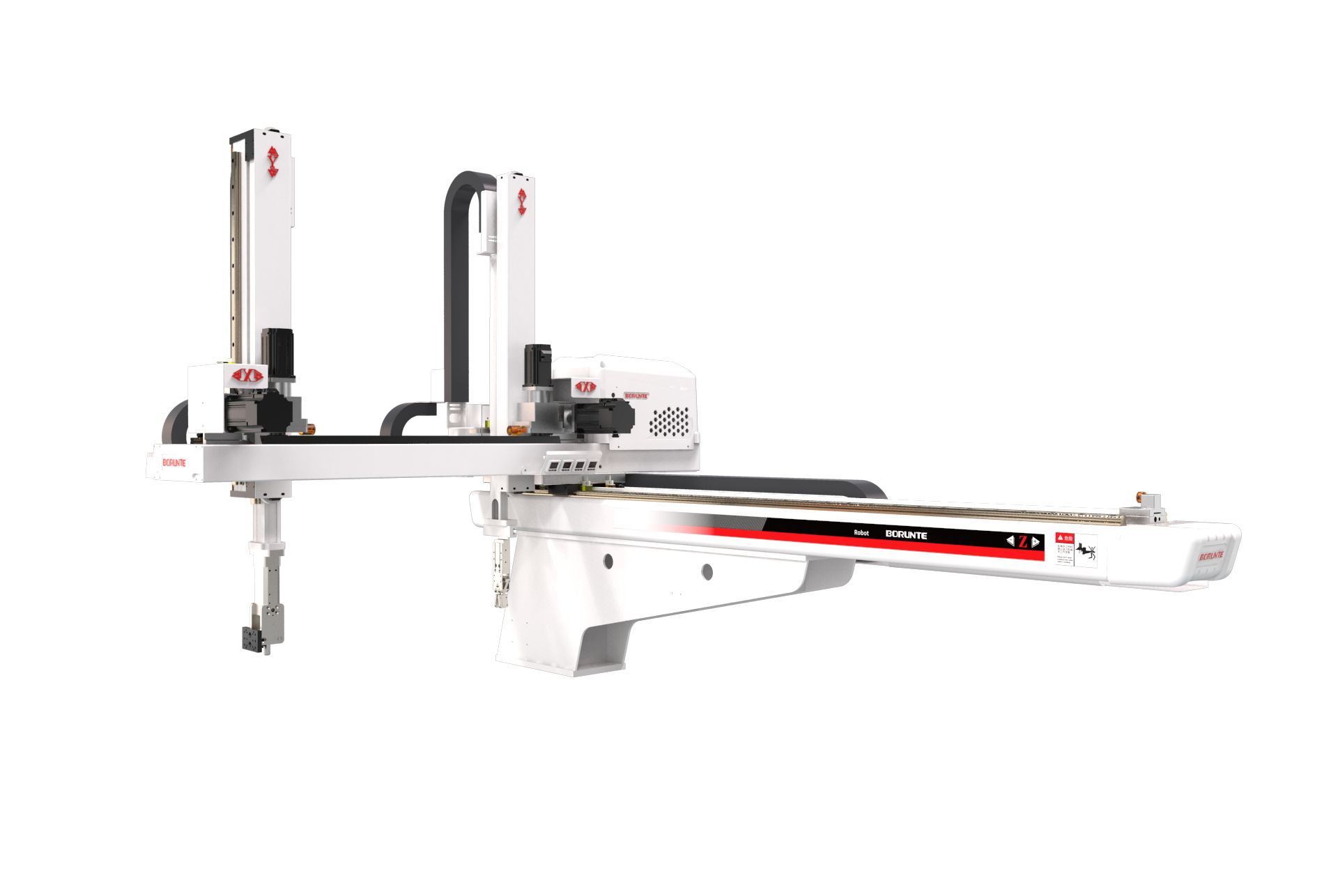

BRTR09WDS5P0/F0 Five-servo Manipulator

Product Description

The BRTR09WDS5P0/F0 Five-servo Manipulator is a high-performance manipulator designed by Borunte for all types of horizontal injection molding machines ranging from 160T-320T. This advanced device is specifically tailored for the take-out of products and sprue, and it is also suitable for in-mold labeling and in-mold inserting applications.

Design Features

- Vertical Arm with Telescopic Stage: The vertical arm is equipped with a telescopic stage, providing enhanced flexibility and reach.

- Product Arm: Designed to handle a variety of products and sprue efficiently.

- Five-Axis AC Servo Drive: Ensures fast and accurate movement, making it ideal for rapid and precise product handling.

Performance Benefits

- Fast Speed: The five-axis AC servo drive allows for quick take-out and in-mold operations, reducing cycle times.

- Accurate Positioning: High precision in movement ensures consistent and reliable product handling.

- Long Life: The robust design and high-quality components contribute to a longer operational life.

- Low Failure Rate: Minimizes breakdowns and downtime, ensuring continuous and smooth production.

Production Enhancements

- Increased Productivity: Installation of the BRTR09WDS5P0/F0 can increase production capacity by 10-30%.

- Reduced Defective Rate: Helps in maintaining high product quality by reducing defects.

- Operator Safety: Ensures a safer work environment by automating repetitive and potentially hazardous tasks.

- Manpower Reduction: Automates labor-intensive tasks, allowing factory personnel to focus on more value-added activities.

- Accurate Output Control: Enables precise control over production volume, reducing waste.

- Timely Delivery: Optimizes the production process to ensure products are delivered on time.

Control System

- Five-Axis Driver and Controller Integrated System:

- Fewer Signal Lines: Simplifies installation and maintenance.

- Long-Distance Communication: Supports reliable operation in large-scale manufacturing environments.

- Good Expansion Performance: Offers excellent adaptability to various production settings.

- Strong Anti-Interference Ability: Ensures high accuracy of repeated positioning and the ability to control multiple axes simultaneously.

- High Accuracy of Repeated Positioning: Consistently achieves accurate positioning, enhancing reliability.

- Simple Equipment Maintenance: Reduces maintenance time and costs, contributing to lower failure rates.

Reliability and Support

- ONE-Year Warranty: Provides comprehensive coverage for two years, offering peace of mind.

The BRTR09WDS5P0/F0 is a reliable and versatile solution for modern manufacturing needs. It promises long-term benefits in terms of efficiency, reliability, and cost savings, making it an essential investment for any factory looking to optimize its horizontal injection molding processes.

Main Specifications

| Power Source(kVA) | Recommended I.M.M (ton) | Traverser Driven | Model of EOAT |

| 2.91 | 160T-320T | AC Servo motor | Four suctions

Two fixtures |

| Traverse Stroke (mm) | Crosswise Stroke (mm) | Vertical Stroke (mm) | Max.Loading(kg) |

| 1500 | P:520-R:520 | 950 | 8 |

| Dry Take Out Time (sec) | Dry Cycle Time(sec) | Air Consumption (NI/cycle) | Weight (kg) |

| 1.5 | 7.63 | 4 | 246 |

Model representation: W:Telescopic type. D.Product arm + runner arm. S5:Five-axis driven by AC Servo Motor(Traverse-axis、Vertical-axis+Crosswise-axis).

The above-mentioned cycle time are the results of our company’s internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

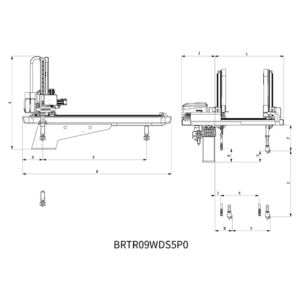

Main Specifications

| A | B | C | D | E |

| 1344 | 2152 | 950 | 292 | 1500 |

| F | G | H | I | J |

| 372 | 161.5 | 194 | 82 | 481 |

| K | L | M | N | |

| 520 | 995 | 282 | 520 |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.