TJG-15T Front outrigger version (manual and automatic)

Product Description

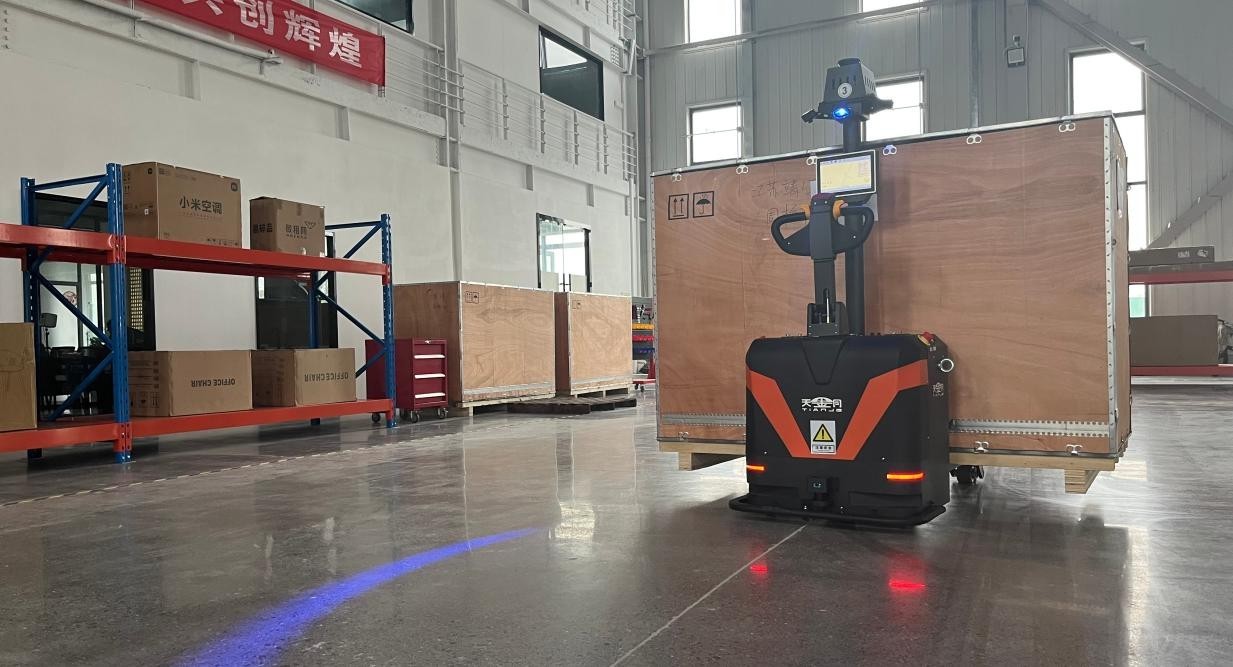

前支腿搬运型(手自一体) Model TJG-15T AGV

Front outrigger version (manual and automatic)

The TJG-15T AGV is a highly versatile automated guided vehicle designed to meet the handling needs of multiple scenarios. It excels in environments where manual and automated operations must coexist, providing a seamless transition between the two modes. In manual mode, the AGV can handle complex forking actions, such as mixed pallet types, irregularly shaped goods, and non-uniform placement. This mode is particularly useful when the handling rhythm is inconsistent or the number of incoming goods “surges.” During material transfer, the AGV mode can be switched on, reducing the intensity of manual work and improving operational efficiency.

One of the key advantages of the TJG-15T is its compact design, which allows it to navigate narrow spaces with ease. Despite its small size, it has a large load capacity, making it suitable for a wide range of industries, including express logistics, 3C electronics, machinery manufacturing, precision manufacturing, medicine, textiles, and food. The AGV’s good flexibility and small turning radius further enhance its adaptability to various material handling scenarios.

Key Features

Manual and AGV Mode Switching

- Use manual mode for complex forking actions.

- Switch to AGV mode during material transfer for reduced manual labor.

- Ideal for environments with mixed pallet types and irregular goods.

Compact and Flexible Design

- Small size with a large load capacity.

- Good flexibility and small turning radius.

- Suitable for narrow space material handling in various industries.

Real-Time Data Collection

- Collects real-time logistics data information.

- Improves the level of intelligence and operational efficiency.

- Enhances decision-making with accurate data.

Multiple Scenario Application

- Applicable to express logistics, 3C electronics, machinery manufacturing, precision manufacturing, medicine, textiles, and food.

- Meets handling needs in environments with irregular placement and varying handling rhythms.

- Handles “surges” in incoming goods without compromising performance.

Space-Saving Solution

- Compact design saves valuable warehouse space.

- Maximizes efficiency in narrow and confined areas.

- Reduces the need for extensive infrastructure modifications.

Enhanced Safety and Reliability

- Equipped with advanced sensors and safety features.

- Ensures safe navigation around obstacles and personnel.

- Reliable performance in various warehouse conditions.

- Low maintenance requirements, reducing operational costs.

The TJG-15T AGV is the perfect solution for modern warehouse and factory managers looking to enhance operational efficiency and flexibility. Its user-friendly design, advanced features, and seamless integration make it a valuable addition to any automated logistics system.

Main Specifications

Basic parameters

| Model | TJG-15T |

| Dimensions L*W*H(mm) | 1770*810*1900 |

| Weight(Batteries included)(Kg) | 400 |

| Standard Load Center Distance (mm) | 600 |

| Load Capacity (Kg) | 1500 |

| Rated Traction Load (Kg) | 1500 |

| Height of rear fork face after fork lowering (mm) | 85 |

| Lifting height (mm) | 120 |

| Mast forward distance(mm) | No door frame |

| Fork Size *e*s(mm) | 1150 170*55 |

| Fork Outer Distance (mm) | 540/600/680 |

| Drive mode | Single steering wheel (three-wheel model) |

| Navigation method | Laser navigation |

| End Positioning (non-standard, optional) | Laser/QR code/3D camera |

| Operation Mode | Manual/Automatic/Semi-automatic |

Battery Performance

| Battery Type | Lithium Iron Phosphate |

| Battery Rated Voltage (V) | 24 |

| Battery capacity (Ah) (automatic charging) | 60/90 |

| Charging station input voltage | 220V(Five-core industrial plug) |

| Charging station output | 24V/50A |

| Hand charger specifications | 24V/30A |

| Working time under rated conditions (h) | 3~4/6~8 |

| Charging method | Manual charging/automatic charging/manual battery replacement |

| Charging time manual/automatic (h) | “60Ah: 2/2 90Ah: 3/2” |

Sports performance

| Maximum operating speed (full load/no load) (km/h) | 4/5 |

| Maximum climbing ability (full load/no load) | 3%/5% |

| Walking Direction | Forward/Backward/Turn Left/Turn Right |

| Positioning accuracy (mm) | ±10 |

| Positioning angle accuracy (°) | ±1° |

| “Single-lane straight-line driving channel width (mm), pallet 1000×1200 (across the fork)” | 1300 |

| “Double-lane straight-line driving channel width (mm), pallet 1000×1200 (across the fork)” | 2600 |

| “Single-side single-row access channel width (mm), pallet 1000×1200 (across the fork) (minimum right-angle stacking channel width)” | 2390 |

| “Double-sided double-row pick-up and release channel width (mm), pallet 1000×1200 (across the fork)” | 3760 |

On-site conditions

| “Minimum right-angle stacking channel width,

pallet is 1000×1200 (across the forks)” |

2390 |

| Operating temperature | 0-55℃ |

| Seam Capacity (mm) | 10 |

| Ground flatness (mm/㎡) | ±5 |

| Automatic charging pile corresponding model | iACS-D29.2V/50A |

Safety performance

| Laser obstacle avoidance | √ |

| 3D Stereo Vision Obstacle Avoidance | √ |

| Mechanical anti-collision/safety edge | Safety edge |

| Fork tine detection | √ |

| Emergency stop button | √ |

| Cargo Inspection | √ |

| Sound and light alarm | √ |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.