With the continuous development of the automation industry, more and more factories are using a complete set of automated assembly line equipment to achieve dark factories. However, considering the development level of different countries, the size of the factory and the cost of automation equipment. Small and medium-sized factories are facing tremendous pressure in this era of automation.

As for the last link of the assembly line terminal, “palletizing”, large factories use various forms of palletizing automation equipment such as robotic arms and column palletizers to replace manual labor. However, the starting price of the common palletizing equipment on the market is more than 1,500 US dollars, and the palletizing equipment is usually fixed in one position, which is inconvenient to move with the assembly line. For small and medium-sized factories, blindly adopting automated equipment cannot achieve the purpose of reducing production costs. In addition, in most developing countries, the automation equipment industry is not perfect, and often encounters the situation where the equipment is purchased but does not know how to install, debug and manage it later, resulting in the intelligent equipment becoming a pile of scrap iron.

The managers of the vast number of small and medium-sized factories need to be clearly aware of such a problem. Importing automated equipment from other countries, such as China, does not mean that it can help your factory achieve automation. The later maintenance cost is sometimes greater than the price of the equipment. What kind of factory can use automated equipment? At least the following conditions must be met. 1. The local labor cost is increasing year by year, and the efficiency of labor cannot be further increased under the existing management model. 2. The local factory conditions can find relevant technicians for automation debugging to carry out later equipment maintenance. 3. When choosing automation equipment, if you are a small or medium-sized factory, the degree of automation itself is not very high, and there is a lack of technicians, then you should choose some simple-to-operate automation equipment to reduce the cost of later equipment maintenance.

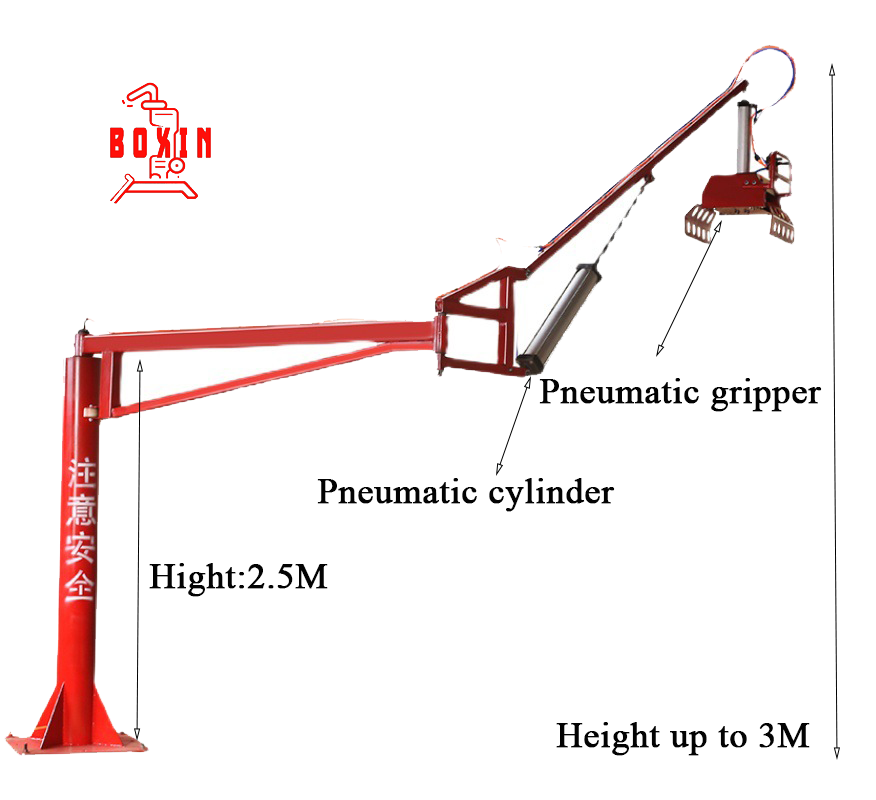

The best entry point for small and medium-sized factories to try automation is the palletizing link. By using BOXIN’s auxiliary palletizing gripper(https://boxin-tech.com.cn/wp-admin/post.php?post=1052&action=edit), we can save 1 person from the original 3-4-person palletizing team. This auxiliary palletizing gripper robot arm can be equipped with a trolley to achieve multi-site mobile palletizing and single-person operation, saving labor and greatly reducing the cost of palletizing. And because this auxiliary gripper is essentially a pneumatic gripper tool, it does not require programming and debugging, which is a good choice for factories that lack technicians. It is very suitable for factories that produce heavy products such as cement plants and wood plants.

This auxiliary gripper can improve the efficiency of the factory, while avoiding the initial investment in large amounts of automation equipment costs, and play a transitional role in the upgrade of small and medium-sized factories.