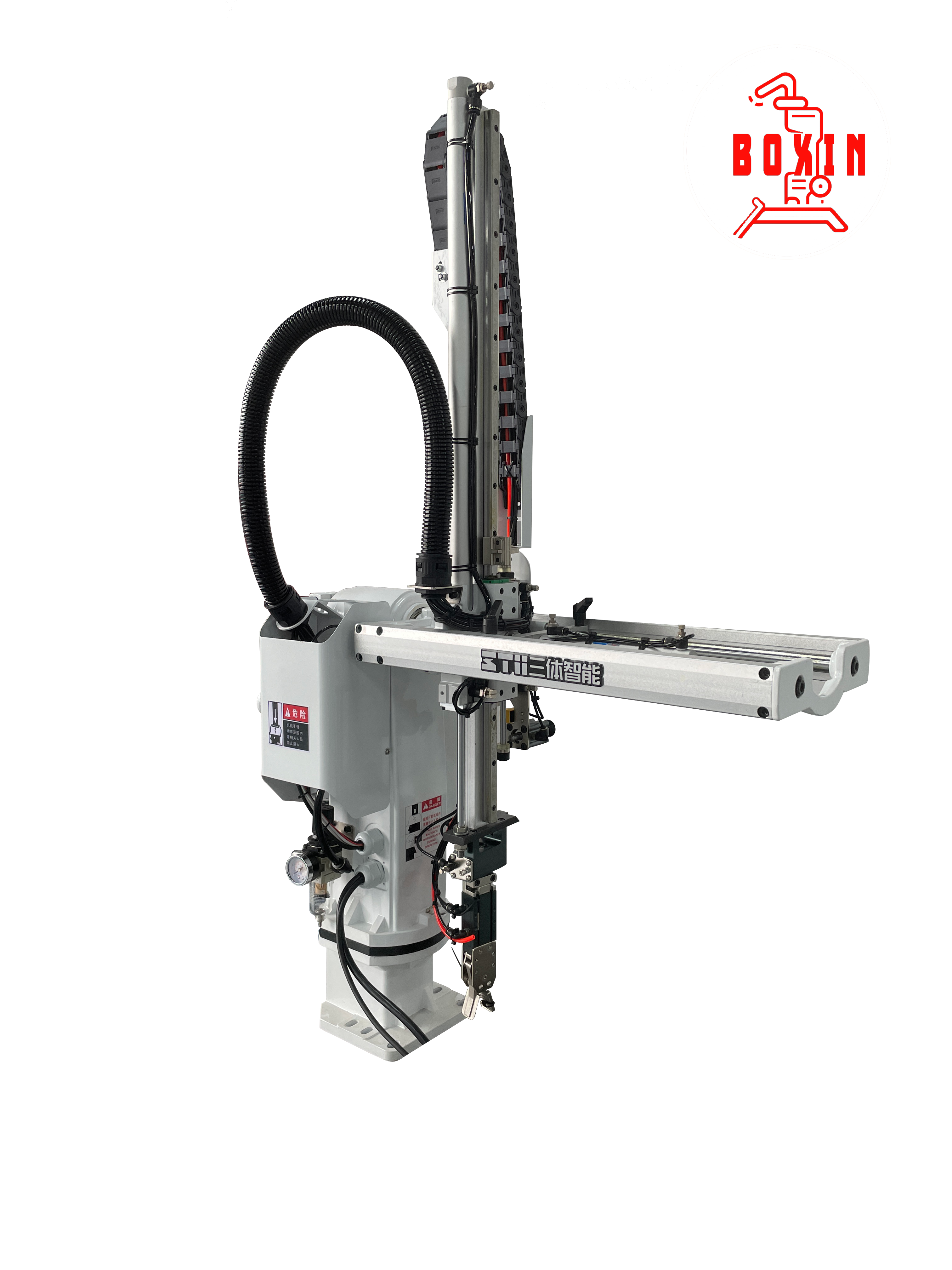

Inclined Arm Manipulator

Product Description

The Inclined Arm Manipulator is a specialized robotic solution designed for injection molding machines ranging from 30 to 160 tons. It excels in the efficient removal of products and water outlets from two-plate molds, ensuring high productivity and precision. The manipulator features a 90-degree rotatable clamp, which allows for rapid and precise product removal. Constructed from durable aluminum alloy and manufactured with CNC precision, it is built to withstand high-speed movements and maintain stability over time. Available in both single-section and double-section arm varieties, this manipulator offers versatile options for clamping water outlets and sucking up finished products. The guide system ensures smooth and controlled movements, while the handheld control system provides an intuitive and user-friendly experience. Backed by a two-year warranty and comprehensive OEM support, the Inclined Arm Series is a reliable and robust solution for your injection molding needs.

Key Features

Tailored for Injection Molding Machines

- Suitable for machines from 30 to 160 tons.

- Facilitates the removal of products and water outlets from two-plate molds.

- Enhances efficiency and productivity in injection molding operations.

90-Degree Rotatable Clamp

- Allows for rapid and precise product removal.

- Improves handling speed and reduces downtime.

- Ensures consistent and high-quality product extraction.

Durable and Stable Construction

- Made from aluminum alloy for durability.

- Manufactured with CNC precision for stability.

- Endures high-speed movements without compromising performance.

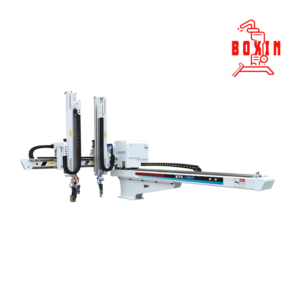

Versatile Arm Options

- Available in single-section and double-section varieties.

- Single-section arms for simpler tasks.

- Double-section arms for more complex and extended reach requirements.

Clamping and Suction Capabilities

- Options for clamping water outlets.

- Suction capabilities for picking up finished products.

- Adaptable to various mold and product types.

Smooth Guide System

- Ensures controlled and smooth movements.

- Reduces wear and tear on the manipulator.

- Enhances overall reliability and longevity.

User-Friendly Handheld Control

- Intuitive and easy to use.

- Provides precise control over the manipulator’s movements.

- Minimizes the learning curve for operators.

Comprehensive Support and Warranty

- Backed by a two-year warranty.

- Support customization and OEM

- Ensures long-term reliability and customer satisfaction.

The Inclined Arm Manipulator is the ideal choice for injection molding factories and production managers looking to optimize their operations. Its robust design, versatile capabilities, and user-friendly control system make it a reliable and efficient solution for product and water outlet removal.

Introduction to Injection Molding Manipulators Manufactured in China

Main Specifications

|

Model |

Power Source(kVA) | Recommended I.M.M (ton) | Traverser Driven | Model of EOAT | Traverse Stroke (mm) | Crosswise Stroke (mm) | Vertical Stroke (mm) | Max.Loading (kg) | Dry Take Out Time (sec) | Dry Cycle Time(sec) | Air Consumption (NI/cycle) | Weight (kg) |

|

STP-600 |

3 |

60T-160T |

Pneumatic | Gripping function | / |

470 |

600 |

2 |

1.3 |

5 |

5 |

39 |

| STP-700 | 120-200T | 500 | 700 |

45 |

Model representation :I: Single section type W: Telescopic type S: Single arm D: Product arm+ runner arm. S3: Three-axis driven by AC Servo Motor S5: Five-axis driven by AC Servo Motor (Traverse-axis、Vertical-axis + Crosswise-axis)

The above-mentioned cycle time are the results of our company’s internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.