Welding workstation drive robotic welding efficiency. More than just a robot and torch, these integrated systems boost precision, consistency, and productivity in modern manufacturing. They optimize every component—robotic arm, welding power source, positioning fixtures, and safety enclosures—for applications like metal frames, automotive parts, and custom fabrications.

System Components

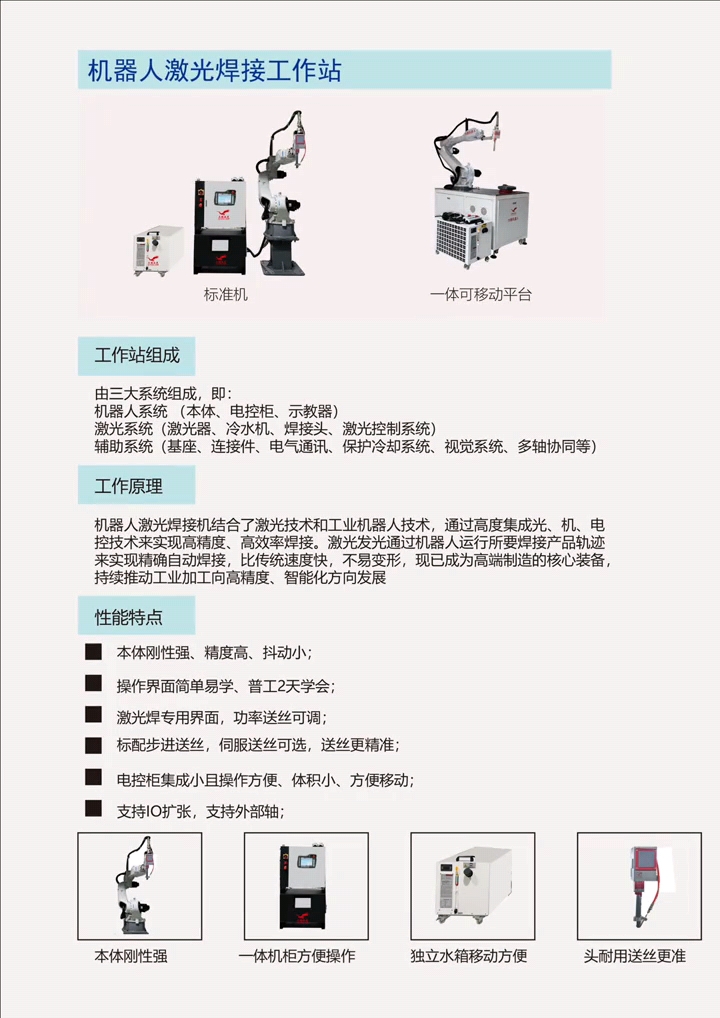

The robotic laser welding workstation includes three main systems:

- Robot System: robot arm, control cabinet, and teach pendant

- Laser System: laser source, chiller, welding head, and laser control unit

- Auxiliary System: base, connectors, electrical communication, cooling system, vision system, and multi-axis support

How It Works

The robotic laser welding workstation combines laser welding and industrial robotics. The robot follows the welding path with high precision using a laser beam. It delivers fast, accurate, and efficient welding. This solution reduces deformation and increases speed compared to traditional welding. It is widely used in smart manufacturing for metal products and components.

Key Features

- Strong and rigid robot body for stable welding

- High precision with minimal vibration

- Easy-to-use interface – workers can learn in just 2 days

- Laser welding interface with adjustable power and wire feed

- Stepper wire feeder included; optional servo wire feeder for higher accuracy

- Compact control cabinet – space-saving and easy to move

- Supports I/O expansion and external axis integration

Applications

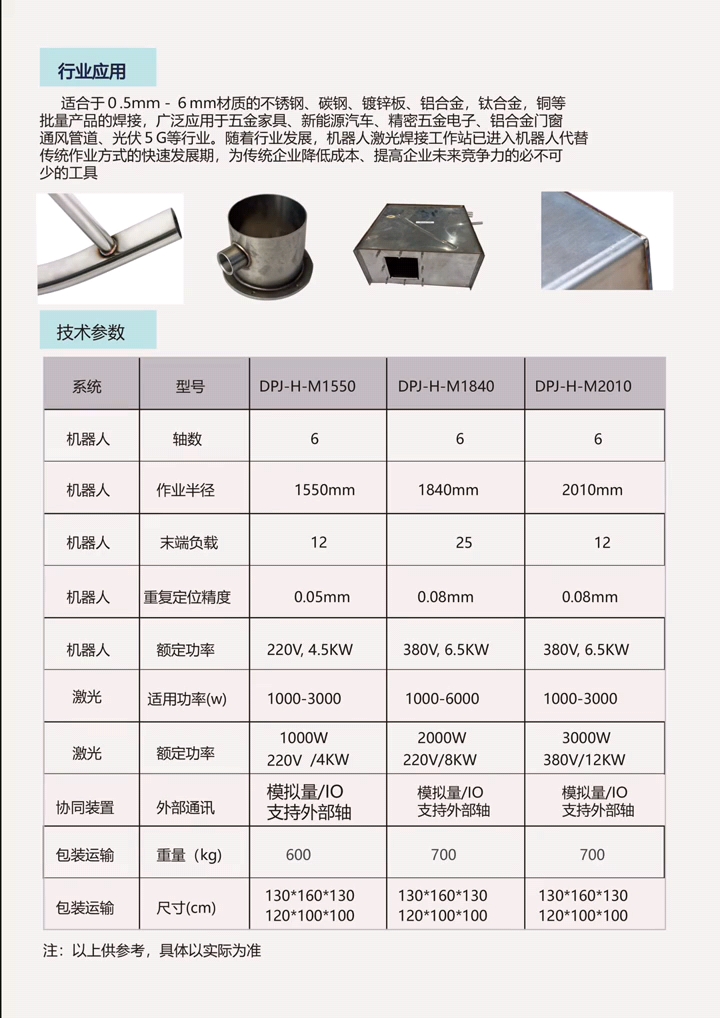

This welding solution is ideal for 0.5mm to 6mm thick materials, including:

- Stainless steel

- Carbon steel

- Galvanized sheet

- Aluminum alloy

- Copper

Common industries using robotic welding workstations:

- Metal furniture manufacturing

- New energy vehicle parts

- Precision hardware and electronics

- Aluminum window and door production

- HVAC ductwork

- Photovoltaic and 5G equipment

As manufacturing shifts toward automation, robotic welding systems help reduce labor costs and improve product consistency. They are key tools for companies looking to stay competitive in the welding industry.

https://kinetictechllc.com/blog/robotic-welding-cell/?utm_source=chatgpt.com